Ubiquitous Assimilation — meaning to absorb everything everywhere all the time.

This is a quote form a film I watched a few weeks back called Detachment, its really worth a watch and this phrase stuck with me. Theres a whole lot more to the quote but its better you watch the film rather than hear it from me!

Its been a while since I’ve posted (again), were well into 2015, the last third of the first quarter to be more precise and I’ve been busy for pretty much every day of it. So where to start after a rather long blog hiatus? To save the potential bore if going over the past few month and trying to catch up ill start from right now!

Right now I’m in Milan in the final stages of quite a long project I’ve been doing for Stage One and were building the UK pavilion for the Milan Expo. The element i have been working on is the LED lighting in a structure called The Hive which is made up of an intricate system of aluminium rods and plate. This forms a 14m square cube with a spherical voice in the middle in which visitors can enter. Around this void is scattered one thousand individually controllable high power custom LED lights. These will resonate with colour which is derived from he audio stream of a real beehive back in the UK and with some processing and algorithms specified by Martin Bencsik, who has done in depth research on bee’s and their activity, we will convert this into a visual stream shown as colours in the Hive.

For a better description in the form of a 3D render have look at the website of Wolfgang Butress, the architect who came up with the design for the Hive. In a nutshell heres a photo rundown and explanation of the progress.

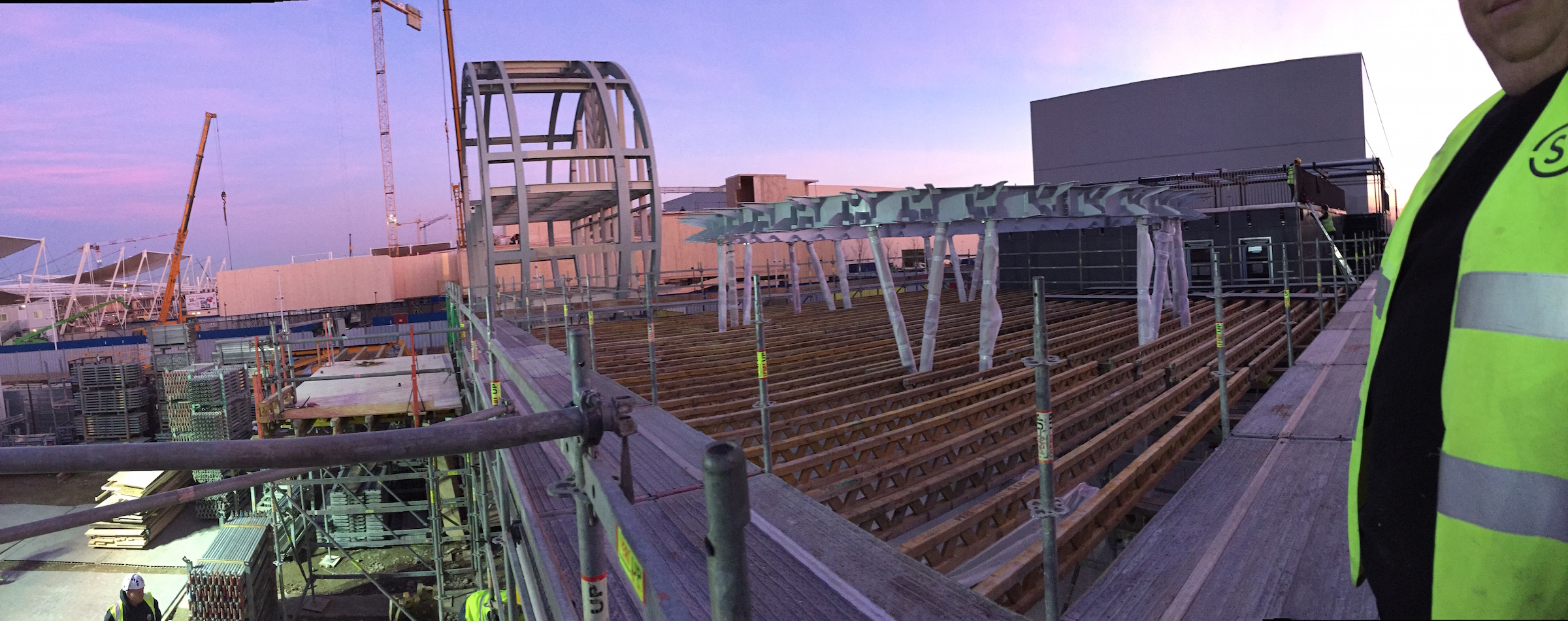

This is the supporting wooden and scaffold substructure which the hive is being built on, and as each layer is built and gets progressively higher it meets with the ring beam which is the grey ring poking up. The substructure is temporary, this will eventually be taken away and the whole hive will be supported on the ring beam.

The earlier days onsite were very cold and very wet, this is us measuring out the wooden template position proper to the first parts being laid down. It really was pissing down hard with rain this evening.

And here we have it, layer 1, made up of many water jet cut aluminium plate and hundreds of bolts and connecting nodes. Myself and Jon my colleague came out to fit the initial LED rings as the structure was built, but as there was no structure we all jumped in to help things progress.

During the build of the first few layers the weather was rather cold, sometimes snowed and was always below zero. On many occasions if we had to loosen bolts to fit nodes, we first had to get a heat gun to melt the ice which had frozen in the bolt hole before we could get an allen key in. The ice was treacherous when walking around and over the aluminium and thankfully no one slipped as the edges of the aluminium are incredibly sharp.

The first 5 layers of the hive are densely populated and the LED we were installing are inside this forrest of aluminium rods. This meant that once the next layer goes on access to test and potentially fix things is very difficult. The above picture shows Jon in at about ring truss 6, its probably impossible to get in any further until the lower floor is taken away.

The first 5 LED rings were installed and left for 4 weeks as we went back to Yorkshire to manufacture address and these fur following 22 rings. This meant that these were left out to the elements and I was quite nervous on who the electronics would hold up in the damp and the cold. We made the units watertight at every opportunity and when we came to test them the only problems we had was a wrong DMX address on one of the pixels! Hooray!

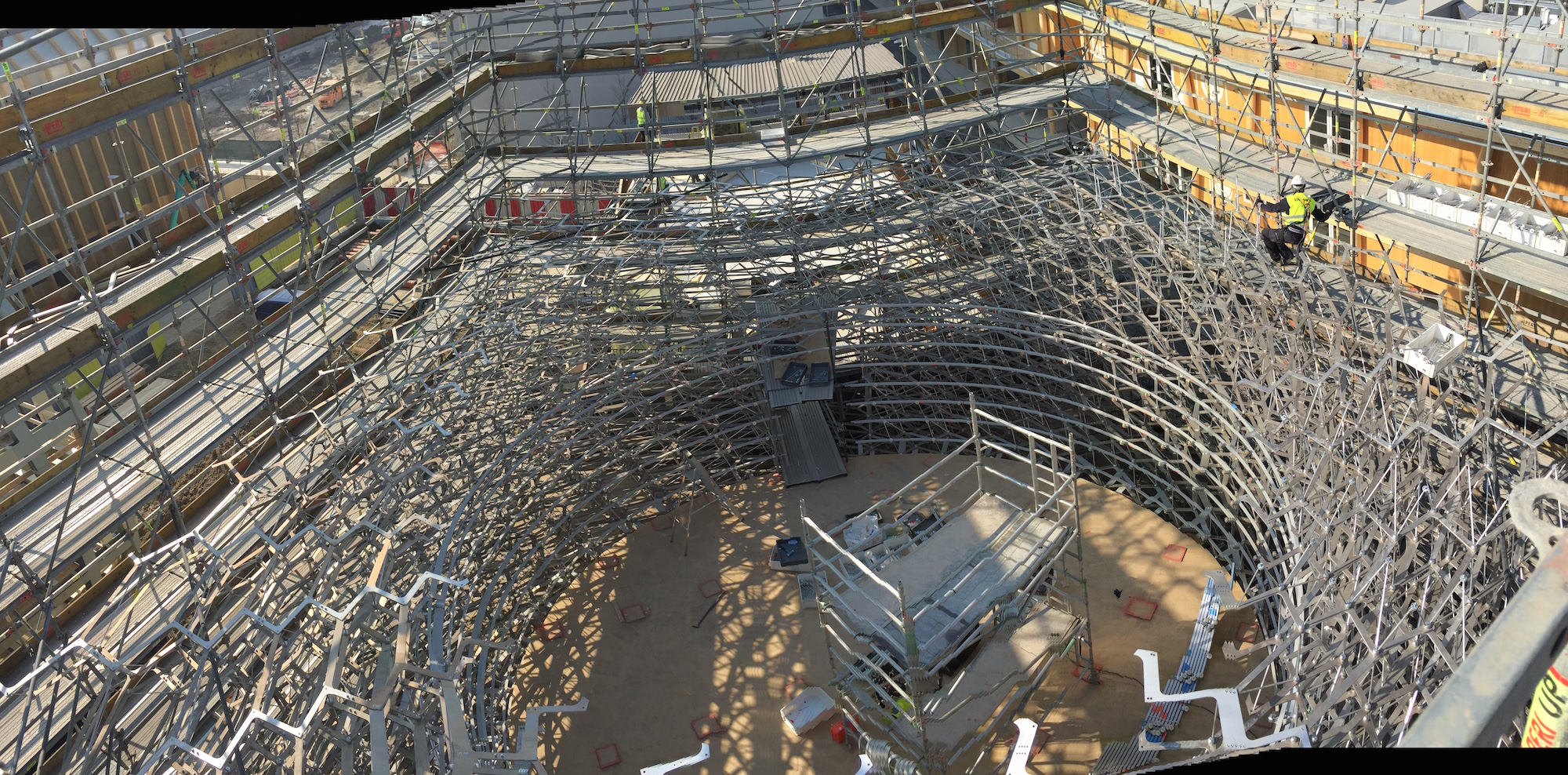

This is a panorama looking down from the top of the hive and the image is somewhat distorted by the panorama feature on the iPhone. I think this shows us up to layer 20 here. As each layer goes in we follow with the next LED ring, each of which has it’s own polar offset to match the lighting layout pattern as specced by the architects.

This is Jon clipped onto the hive at layer 15, this is about 4 meters up from the temporary floor and I’m around 6 meters up. Sometimes when the element of the hive which we need to fit LED onto aren’t ready we will switch rolls and help with the assembly of the hive, its a varied job.

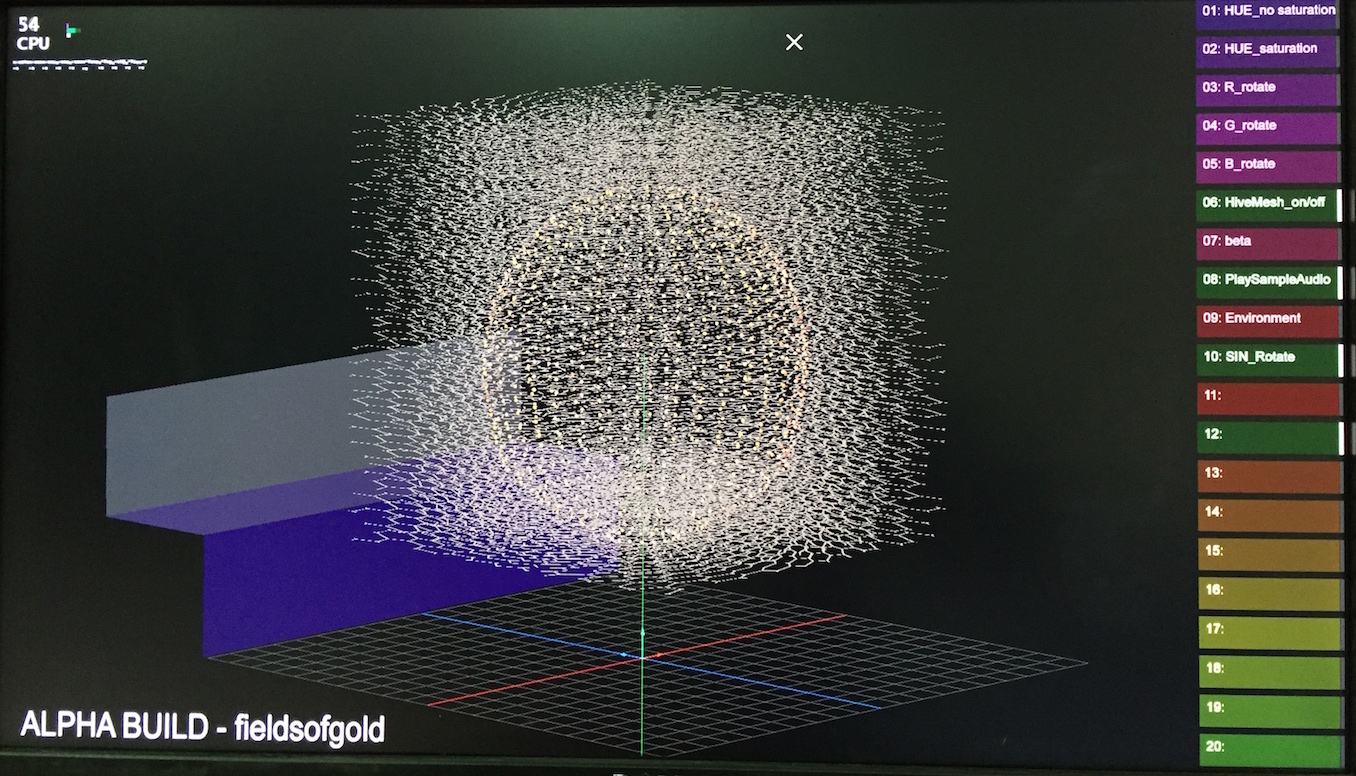

Above is a screenshot of the LED control software, which is still been tweaked and worked on. Here we take in the live audio stream of the real beehive and analyse the spectrum. This is then used to create an image based on the various frequencies over time and then we pixel map this to the sphere. From there this is then converted to DMX via Art-net and output to the pixels spread over 8 universes. Im looking forward to getting this all up and running in the next few weeks.

As I say the above is just a whisker of the work which has gone into this and is still ongoing, theres still allot to do, but there is a good team here and things are progressing.

To finish off, heres a face I found in my potato a few weeks back!